As I get more serious into my electronics hobby, I need to work with more SMD components. Some component packages are very difficult or impossible to solder with a traditional soldering iron. To solve this problem, I decided to hack a toaster oven to become a reflow soldering oven.

Basically, to perform reflow soldering, solder paste is placed on a printed circuit board, and the components to be soldered is placed on top of the solder paste. When the oven heats the solder paste past the melting temperature, the solder paste melts and solders the component to the circuit board.

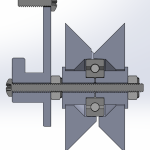

To control the oven’s temperature, I created my own reflow toaster oven controller circuit. This circuit uses an ATmega32U4 microcontroller to monitor the oven’s temperature using a thermocouple and AD595AQ, and then control the oven’s heating element using a solid state relay. The controller features USB logging/debugging, USB bootloading, a graphic LCD display, and 3 buttons. The firmware features tweaking for all settings, manual temperature control, manual heating element control, and automatic temperature profile control (with a nice temperature history graph display). This circuit will plug into a wall outlet, and the oven will plug into this circuit, while the solid state relay basically acts as a switch between the wall outlet and the oven’s heating element. Safety is the main design objective (but some things were limited by cost), and ease of use is the second objective.

Visit the Instructable Here. This links to the full guide where I show you how to build this project step by step.