Remember my Aquarium Computer? I thought the SSD looked boring, so I put a old-school HDD inside with all the guts exposed, and wired it electrically to spin and swing when there is hard drive activity (when the HDD activity LED blinks).

But I have a deep dark secret…

OK I’ll be honest, this is a “failed” project. I considered it a failure because I got lazy and used a MTD6501 chip to spin the platter, but it always spins for a little bit and just stops. I don’t know why, I don’t see the power dipping on o’scope traces. That chip is designed for driving things like cooling fans.

Another reason why I think it’s a “failed” project is because IT IS ANNOYING AS HELL BECAUSE IT IS SO GOD DAMN FUCKING LOUD. Obviously it’s because my primitive circuit is simply using a MOSFET to shoot as much current through the coil as possible, thus smashing it from end to end. A better circuit would obviously use some form of current control, and obviously a real HDD circuit would control the coil with micrometer precision.

But it was still fun. I leave it disconnected.

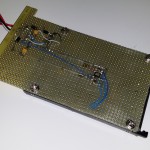

Here is the rough circuit:

Yes, I understand I can make huge improvements, but I did it with spare parts in one day. Remember to check the polarity of the read head voice coil first!

On a side note, if you simply power up a PATA HDD, it will spin without adding your own motor driver. But if you attempt to mess with the read head, I suspect it fails some sort of “self-test” and won’t spin anymore. Another approach to this project is to get a MCU with enough pins to use the PATA interface itself and actually perform random read operations.

A previous attempt of this project used power from the motherboard directly, but that caused my computer to not boot, I think the primitive way I am driving the voice coil is drawing too much current. This current implementation uses power from a 5V wall wart instead.

When I have time, I will reattempt this using a small microcontroller and PWM to control the voice coil.