Orrery – Laser Cut Wood Project

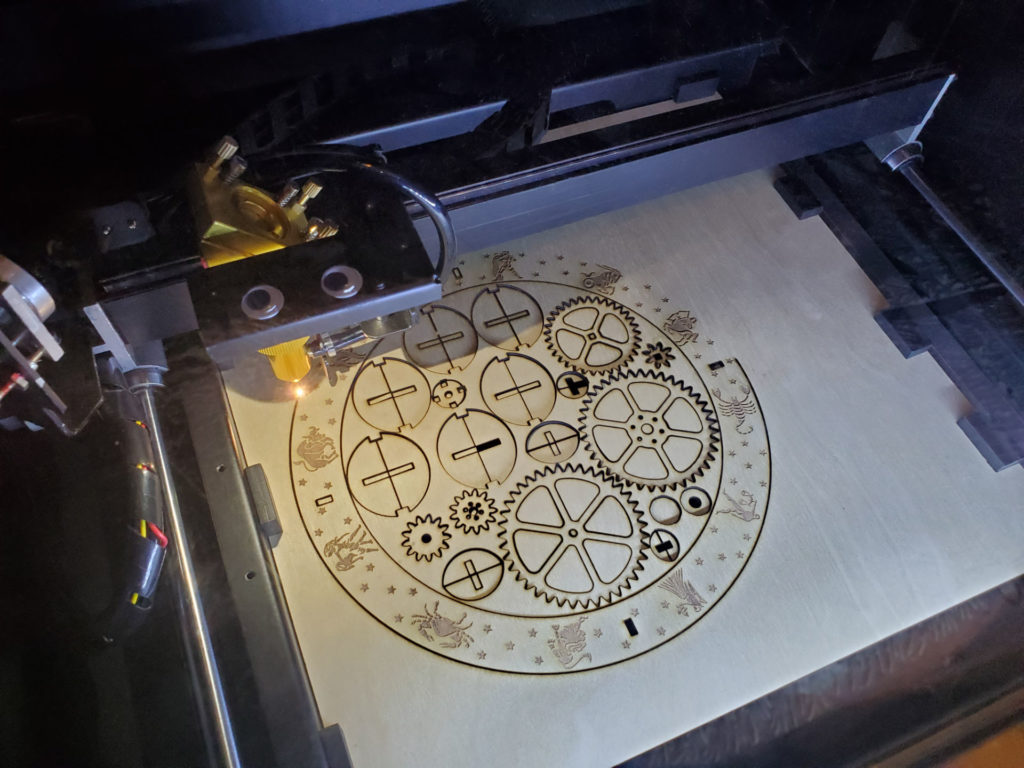

I’m having so much fun with my new Beamo laser cutter! I designed and made this wooden orrery with my Beamo. It’s a mechanical toy that depicts the position of the Earth and Moon as they orbit each other and the Sun, with artwork showing the moon phases and Zodiac. See more pictures and animation:

All files are open source and available on my GitHub repo (click here)!

I have provided the two SVG files to be cut on the laser cutter, optimized for the Beamo but should work on any other laser. The 3D models I designed using SolidWorks is also available. Assembly instructions are provided in the repo as well.

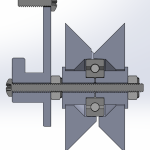

Originally designed in SolidWorks. The parts were then exported to SolidWorks drawing files, then exported to DXF files, then imported into Inkscape to be edited as SVG files.

Inside Inkscape, paths were joined together to optimize cutting. Paths that represented circles, squares, and slots, were converted into basic shapes so cut tolerances can be adjusted. Finally, the cutting order was organized into layers. Beam Studio will import the layers in the order you defined them.

I learned the hard way that you need to make inner cuts first before outer cuts. Otherwise, if you do an outer cut first, the piece will move after being cut free and fall onto the laser’s honeycomb bed. This means the inner cut will be off target.

I also discovered that you can flatten plywood down onto the honeycomb bed using magnets!

All the artwork had to be tested to see if the resolution of the laser was enough, and re-adjusted if lines were too thin or too thick. I did this with a test etch on a piece of scrap wood.

The gears were generated by https://geargenerator.com/. The gear ratios make the Moon phases and Earth seasons reasonably accurate (view the screenshot to see the ratios being used). The DXF files were imported into SolidWorks.

The above screenshot shows how the gear diameters and positions were determined. The circles in the drawing indicate the gears’ pitch diameter, and those circles are tangentially constrained together.

Gear Generator’s output is very complex (thousands of line segments) and makes SVG processing much harder, so the imported image was simplified down to one tooth, the complex segmented curvature is simplified down to one arc. The sketch is shown in the screenshot above.